BONAXLE® is innovative induction-hardened axle. It is our solution to the requirements of increased safety and reliability. It also brings significant decrease of life-cycle costs (LCC). BONAXLE® is likely to bring paradigmatic change in railways across Europe and beyond. GHH-BONATRANS achieved to improve the technology already well established in Japan by adapting it to the conventional European geometry and steel grades.

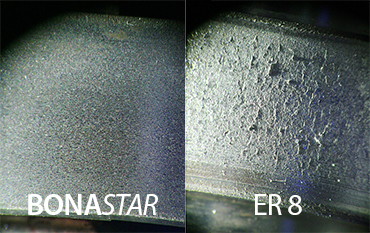

BONASTAR® is a range of enhanced steel grades used for the manufacture of all types of carriage, locomotive and freight truck wheels (solid wheels as well as tyres). They fully meet the requirements of applicable standards, but compared to standard grades give the user significant benefits, such as a 30% longer life. This considerably longer life in terms of the mileage is the result of the enhanced fatigue life of the wheel web and the higher hardness and strength of its rim and, last but not the least, the (unreduced) high level of plasticity. Thus ultimately BONASTAR® reduces the wheelset’s LCC and increases its reliability and safety.

BONASILENCE® is a family of dynamic noise absorbing systems developed and being diversified by GHH-BONATRANS. You can find latest example in the new metro cars for Berliner Verkehrsbetriebe (BVG) supplied by Stadler. Driving and standard wheelsets are equipped with multi-segmented dampers, mounted on the wheels, being able to reduce the wheel rolling noise by 10dB in comparison with standard wheels. The dampers significantly reduce squealing noise too. Expected lifespan of the damper is minimum 15 years. Analogical damper can be designed to fit any wheel diameter.

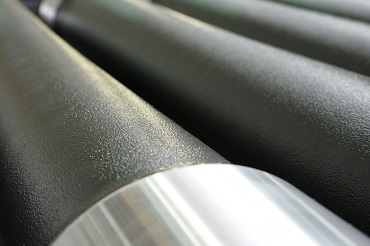

BONACOAT® is a range of coating systems for the protection of wheelsets (and their components) of high-speed trains and other rail vehicles for transporting passengers and freight. It increases the wheelset’s resilience against mechanical damage, corrosion and cyclic stresses. BONACOAT® significantly contributes towards the reduction of the wheelset’s LCC, and increases its operation safety.

BONACOAT® meets also the requirements of the ERWA Guideline for Axle Coating, in which the European manufacturers of wheelsets and their components have accumulated their know-how acquired from dozens of years of direct cooperation with the operators, manufacturers and repair facilities of rail vehicles. The scope and structure of these requirements originated in ERWA (The European Railway Wheels Association, part of UNIFE) committees between 2016 and 2021, with the aim to improve the protection of axles and increase the reliability and competitiveness of the railway transport.

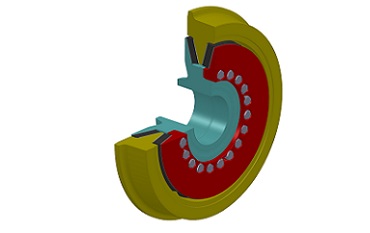

The newly developed super-resilient wheel GHH®ULTRA-S for 12.5 t axle load meets all requirements for a resilient wheel with tread diameter of 600mm new / 520mm worn and secures low radial stiffness (20-40 kN/mm). The design of all components has been enhanced and the rubber elements have been completely reshaped. Excellent strength of the GHH®ULTRA-S was verified by applying the German quality standards (FEM analysis and assessment of stresses by application of FKM-guideline).

Independent wheel axles 12.5 ton

Having started with the introduction of this technology in Europe more than 30 years ago, nowadays nearly all tenders for new trams and light rail vehicles (LRV) worldwide call for low-floor vehicles. These vehicles need to be designed for high transport capacity.

The new 12.5t independent wheel axle is based on the proven and reliable GHH®V60 wheel type. Its modern upgrade for high axle loads is based on a one-piece, die-forged portal axle design and a pair of tapered roller bearings, adjusted optimally during assembly. The wheel diameter is increased to cover the higher axle load requirement. We supply portal axles for both type 1 (inner distances of wheels from 1,355mm to 1,392mm) and type 2 (from 1,380mm and higher) applications.

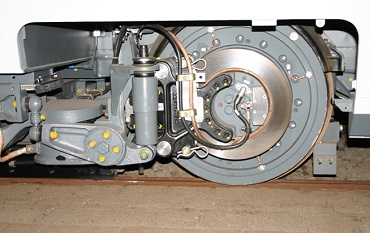

Advanced speed sensor & ground contact system for non-driven independent wheel axles

Our contribution to the upgrade of trailer-independent wheel axles easies the access to all components/subsystems of the wheel axle. The speed sensor and electric ground contact are mounted on the portal axle end. This construction, including the flange-mounted brake discs, uses far less space than other solutions. The extra space can be used for the placement of additional elements, e.g. hydraulic brakes.