Without an axle, there is no wheelset...

PROTECTION FOR BETTER SAFETY AND REALIABILITY

Adhering to life-cycle costs we dedicate our efforts to protect the axle and its lifespan since the initial design phase. Our technological know-how and long-term experience in wheelset production gives us confidence in developing and applying axle adjustments and upgrades, which increase the product safety and reliability.

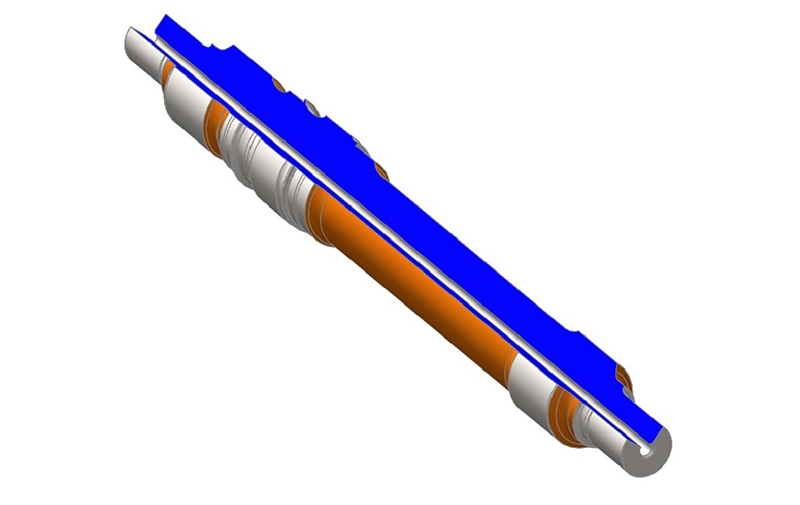

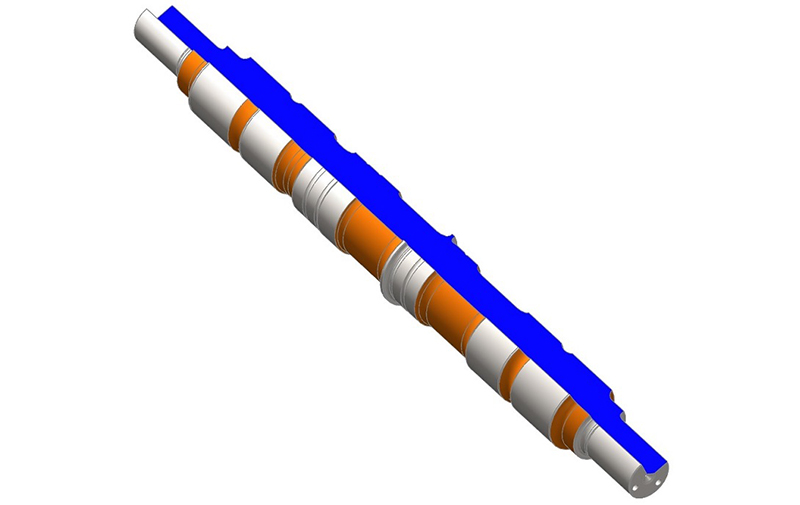

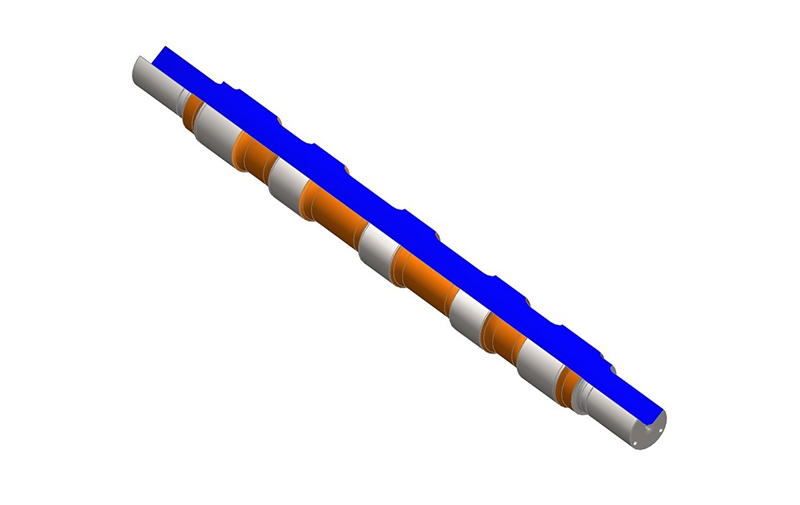

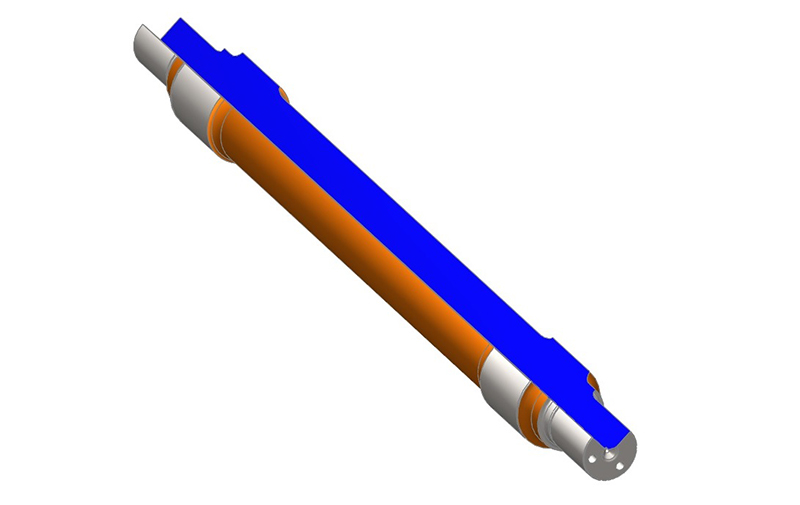

The evidence of our efforts and competence in research and development of axles with improved protection is BONAXLE®. This induction-hardened axle is the most advanced and complex solution available on the market. Selected aspects of protection can be taken care of by molybdenum coating, cold rolling or by a range of special coatings.

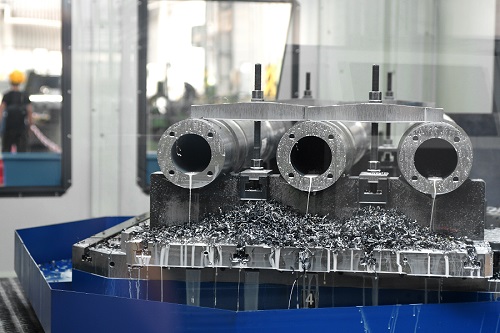

Accuracy is the key

GHH-BONATRANS supplies axles integrated in wheelsets as well as loose axles for the assembly of wheelsets managed by customers (e.g. when a customer mounts the drive or if the supplied axles are used as replacements). Axles for passenger transport, often for high-speed, are characterized by high processing accuracy and a sophisticated quality control system.

Axles are often delivered with a longitudinally drilled hole, which allows easy diagnostics during operation and reduces the wheelset weight. Very diverse international standard requirements must be respected by axle design and production.

- Powered and non-powered axles

- Axles with additional seats (in total up to 6)

- Solid, semi or fully hollow axles, including threaded axles

- Induction-hardened axle BONAXLE®

- Axles with molybdenum coating

- Cold rolled axles

- Axles with special coatings