SERVICES

Skilled personnel and expert consultancy

We offer independent expert reviews of wheelsets and wheelset parts (product design, construction calculations, metallographic analysis, NDT etc.). Professional consultancy, support by product design, testing capacities and experience in product certifications and homologations are provided to all customers entering new markets. We are ready to design and deliver modernisation of current rail vehicles. Our specialists can assist with the launch of new or renovated products into operation.

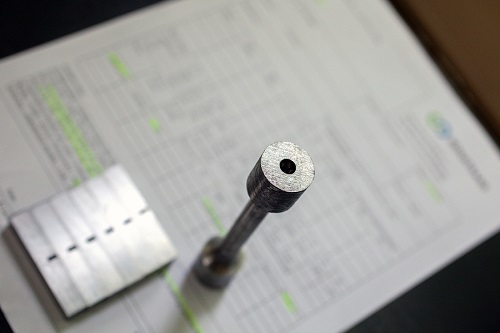

GHH-BONATRANS testing labs are accredited to provide all necessary tests needed for product certification. Noise level measurement and evaluation of noise-reducing measures is also provided. Documentation of products delivered by GHH-BONATRANS are available online for our customers.

Optimised maintenance concept for reduced LCC

GHH-BONATRANS is accompanying its customers during the life cycle of complex systems whilst consequently extending its service capacities. Maintenance of such technically demanding products and systems requires long-term experience and specific know-how. Our competence and proven track record in design and manufacturing as well as best-in-class, reliable equipment and devices enable us to offer one-stop service for the wheelset.

We help our customers reduce the LCC by optimizing the product maintenance and providing precise tracking of products in operation (including remote tracking on metro trains). Preventive and corrective maintenance activities cover disassembly of wheelsets, inspection and repairs of wheels, axles, tyres, rubber segments, bearings, brake discs, gear boxes and coatings, and assembly of the wheelset. We monitor mechanical damage of components and secure their repairs, including wheel re-profiling, non-destructive testing of axles, among others.

- Repairs of wheelsets, wheels, axles (in and after warranty)

- Preventive and corrective maintenance of wheelsets including gearboxes and bearing units

- Heavy overhaul of independent wheel axles and running gears

- Exchange of wheel tyres

- Non-destructive testing and dimensional checks of wheels, axles and wheel components

- Metallic spraying of axle and bearing seats

- Modernisation of wheelsets (including noise reduction)

- Expert consultancy and technical advise

- End-customer training

- Technical assistance with launches into operation

- Homologation testing in own accredited laboratories

- Online product documentation

- LCC and RAMS