Tests

MECHANICAL TESTS

Verification of mechanical properties of (our) products.

- Brinell hardness test

- Vickers hardness test

- Rockwell hardness test

- Impact bending test

- Tensile test

- Fracture toughness test

- Drop weight test (non-accredited test)

- Bending test (non-accredited test)

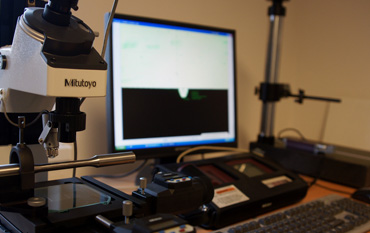

METALLOGRAPHIC TESTS

Verification of the structure and purity of the material of (our) products.

- Baumann test

- Etching test

- Determination of apparent grain size - comparison method

- Determination of share of structural components

- Determination of microcleanness

- Determination of microstructure (non-accredited test)

NON-DESTRUCTIVE TESTS

These tests check that the products do not include any surface or internal defects.

- Ultrasonic test

- Magnetic test

- Eddy-current testing - for hollow axle (non-accredited test)

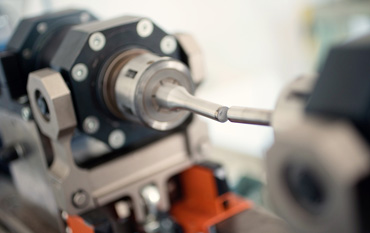

FATIGUE TESTING

Verification of material behaviour under dynamic loading including resistance of coating according to the standards for the railway industry.

- Wheel fatigue test

- Axle fatigue test

- Wheelset fatigue test

- Assessment of coating resistance to cyclic mechanical load

- Assessment of coating resistance to impact

- Assessment of coating resistance to gritting

- Test of stiffness of rubber elements (non-accredited test)

- Laboratory heat treatment (non-accredited test)

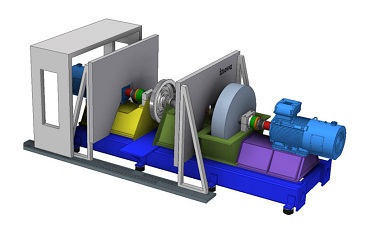

BRAKING TESTS

Verification of the wheels resistance to thermal loading during pads braking.

- The braking test includes testing of two wheels, new one and maximum worn out.

- Braking tests are performed according to EN 13979-1 or according to the specific customer’s specification and requirements.

CHEMICAL TESTS

Determination of C, Mn, Si, P, S, Cr, Ni, Cu, Mo, V, B, Ti, Zr, Co, W, Nb, As, Pb, Sn, Al by optical emission spectrometry method.